Products

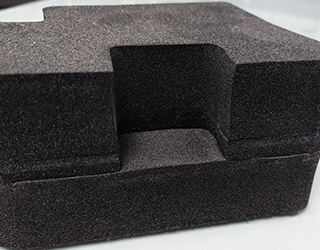

-FOAMS-

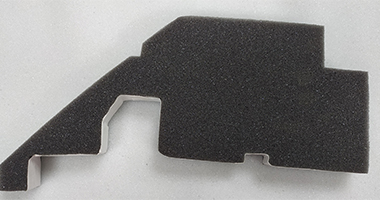

Flexible PU Foam

We manufacture PU foams of a wide range of density, FR/NFR (Fire Retardant and Non-Fire Retardant).

FR foam does not catch fire and hence is a product of high asset for use in specific applications. This type of foam is highly resilient and used in places where stringent fire code standards are needed. They are ideal for use in hospitals, DG sets, automobiles, white goods, construction etc. FR foam has an unusually high density which makes it highly durable. The use of fire retardant chemicals helps in creating a grainy texture that resists fire. FR foam does not melt or drip when exposed to heat or intense flames and can help create a safe environment in commercial establishments. As FR foams are manufactured using special materials and fortified to offer resistance to fire, they are generally more expensive than normal foam products.

The NFR foam is used in common applications like seat lining in automobile, furniture, mattresses, home applications etc. It is less expensive than other types of foams. Normal foams do not offer any resistance to fire and are hence not used in environments where there is a potential risk of fire present.

Properties:

Resistance to wide variety of solvents

Flexible and lightweight

Cushioning

Anti-bacterial protection

Sound absorption

Energy absorption

Heat Insulating

Low thermal conductivity

Low water vapor transmission

Resiliency

Vibration dampening

Applications:

Benefits:

Cost-effective cushioning and comfort

Excellent Sound insulation

Enhanced thermal insulation

Reduced energy consumption

More longevity and durability

Good shock and energy absorption

Applications:

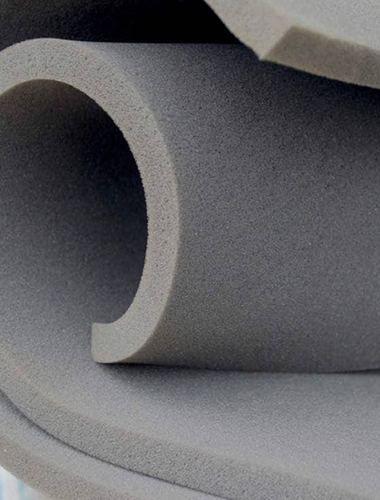

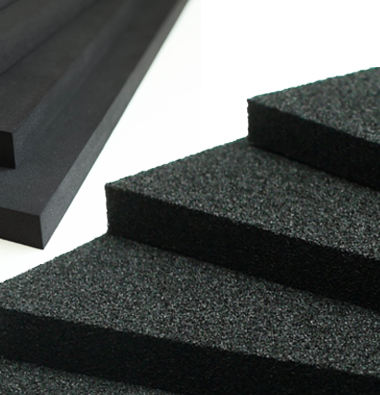

NBR (Nitrile Butadiene Rubber) Foam

NBR foam has closed cells. This makes the material moisture and water repellent. The foam is soft and flexible and its closed cell structure makes it an excellent product for thermal insulation, sound deadening and flame retardance and shock & impact absorbing. It is also an ideal for sealing and gasket material. We supply them as per the customer specifications, full sheets or die cut, with or without adhesive.

Properties:

Closed cell structure

Flexible and lightweight

High thermal efficiency

Sound absorption properties

Flame retardance

Low water absorption rate

Water vapor diffusion resistance

Resistance to oil and grease

Benefits:

Strong thermal and acoustic insulator

Perfect water and moisture barrier

Excellent shock and impact cushioning

Versatile for various of applications and usage

Available for adhesive backing and foils

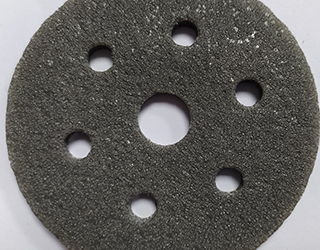

XLPE Foam (Cross Linked Polyethylene Foam)

Cross-Linked Polyethylene Foam is an extremely fine-celled foam, ideal for projects and applications that require thicker foam. With a smooth, pleasant feel combined with superior physical and chemical properties, cross-linked polyethylene foam is the solution for an array of applications that demand thicker sections of closed cell foam.

Properties:

Closed cell structure

Heat insulation

Water and mold resistance

Excellent buoyancy

Flame retardance

Anti-static

Benefits:

Weather and chemical resistance

Excellent shock absorption and vibration dampening

Resistant to water, chemicals solvents and oils

Buoyancy with low water absorption

Non-dusting

Reliable thermal insulation

Applications:

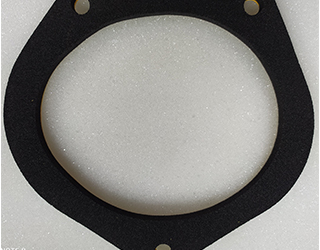

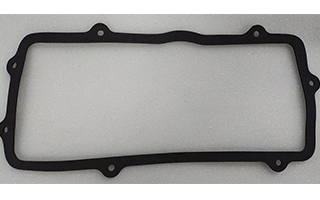

EPDM Foam (Ethylene Propylene Diene Monomer Foam)

EPDM Foam is a high-quality, closed cell material that is commonly used to create an air and watertight seal. It is great for use in outdoor sealing applications due to the superior UV and Ozone resistance the material offers. Aside from offering excellent weathering resistance, EPDM also features good flexibility, tensile strength and recovery properties. The closed cell structure enables the material to handle high-pressure sealing applications at a better rate. The sealing properties of the material can vary depending on the density.

Properties:

Closed cell structure for strong sealing

High resilience and compressive strength

Resistance to aging, moisture, light, ozone, heat

Applications:

Benefits:

Flexible and durable

Weatherproof

Great sealing capability

Excellent cushioning and shock absorption

Can work across different temperatures

SBR (Styrene Butadiene Rubber) Foam

The SBR foam is very similar to natural rubber. It is specially formulated for general industrial purposes and economical substitute to natural rubber. It can be combined with natural rubber to make it even more effective. The exceptional features of SBR is its flexibility, dampening shock and sound, high abrasion resistance as well as resisting efficiently against air, dust and moisture.

It is an affordable replacement for natural rubber due to its, high water resistance, abrasion and aging resistance and flexibility.

SBR has low resistance against fire, hydrocarbon solvents and oil and is difficult to process.

Properties:

Closed cell foam rubber

Shock absorption and vibration dampening

Flexible and resilient

Heat-aging

Resistant to wear and weak acids

Benefits:

Economical material for general sealing and cushion

Applications:

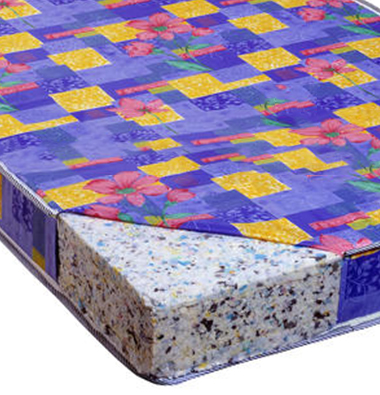

Bonded Foam

A bonded foam mattress is made up of scrap polyurethane foam. It is also called rebounded foam. The PUF scraps are bonded together under high pressure using adhesive to form a hard substance. This foam is usually used for mattresses and furniture. Based on the requirement foam of different densities are made.

Properties

Made from PU scrap. It has the basic properties of PU foam

Applications

Mattress and furniture.

Benefits

Best usage of PU scrap material

Silicon Foam

Silicon foam has the combined properties of resilience, high temperature stability, and general inertness, unavailable in any other foam. They are generally unaffected by extended exposure to temperatures from -60 to 200 degrees centigrade, and are also resistant to aging and degradation from sunlight and ozone. Flame retardant closed cell silicone sponge and silicone foam gaskets are used in analytical instrumentation, telecommunications equipment and controls used in Mass Transit systems. Even when silicone rubber burns under extreme temperatures, the by-products are non-toxic and any residual ash continues to

Properties:

Closed cell foam

Excellent compressive strength, resilience and flexibility

Can withstand extreme temperatures

Excellent sealing against water and dust

Very good resistance to ultraviolet light, ozone and oil

Benefits:

Extremely low water absorption (<1%)

Excellent ozone and UV resistance

Densities from 150 kg/m³ (very soft) to 530 kg/m³ (firm)

Thermally stable over temperature range -60°C to 230°C (250°C)

Easily fabricated into various types of foam gaskets, pads, tapes and sealing profiles

Excellent performance on sealing, cushioning, soundproofing

Resistance to weather, oil, chemical and tearing

Applications:

-TAPES-

Aluminum Tape

Temperature resistance from deep-freeze to oven processing.

Heat conductivity and reflectivity.

Electrical conductivity.

Strength and durability.

Compatibility with foods and pharmaceuticals.

Ease of lamination and coating.

Flexibility

Formability and non-returning dead-fold.

Benefits:

Versatile in handling both hold and cold temperatures

Offers better adhesion and cohesion

Corrosion resistant

Chemical and weather resistant

Applications:

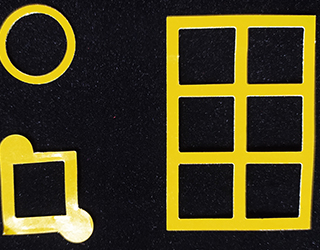

Non-woven double side tape

Non-woven tapes are made with natural or synthetic fibers that have been interlocked mechanically, thermally, or chemically. These types of cloth tapes consist of a variety of materials, including cotton, polyester, or nylon. They are tear able by hand. Their relatively low thickness means they can conform to slightly irregular surfaces.

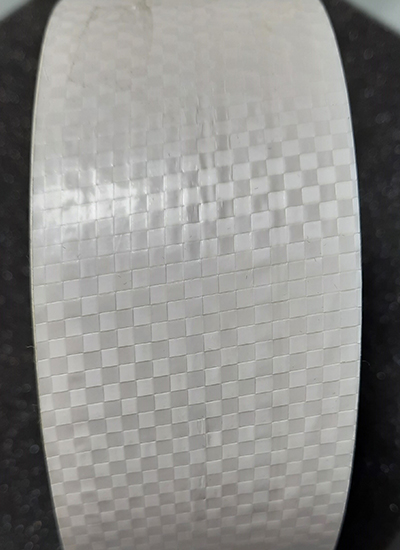

Metalized Polyester tape

A Polyester film, that is metallized on both sides or one side.

Applications:

Polyester tape

Polyester adhesive tapes are suited to various applications which require minimal thickness, high tensile strength, and resistance to ageing and temperature. Single-sided polyester film adhesive tape is thus particularly used for high-temperature masking, jointing, protection and in the field of electronics. It is also used in transformers and electrical relays for temperature application up to 130°in general-purpose insulation.

Foam Black Velvet Tape

The tape is made using fire retardant black velvet and foam with very strong industrial grade adhesive. This make the tape a very good and strong electrical insulator, protects against high temperature and keeps the wiring safe from damage. This makes it ideal for automobile electrical wiring harness.

EPDM Tapes

EPDM closed cell tape are closed cell materials do not allow ingress of air, dust, moisture or water.

Benefits:

The material has excellent ageing properties and therefore does not degrade through time.

It has excellent resistance to UV rays and, as a result, is widely used for outdoor applications.

Resistance to high temperatures and weathering

They are non-conductive

Ability to dissipate stress

Uses:

XLPE Tapes

They can be made in a variety of color, thickness and density. It is an extremely versatile tape.

Benefits:

Excellent holding power; peel strength and adhesion

Anti-shock, heat, and humidity resistance.

Superior stick capabilities to different surfaces such as metal; plastic; paper; wooden and silicon.

Retention

Good chemical resistance

Excellent weather resistance

Applications: