Industries

Industries

Foam is a versatile product. The fact that it is easy to manufacture, lightweight, comes in different flavors which can be tailored to meet different needs, safe, cost-efficient and sustainable finds its use in almost every industry.

Automotive

Monarch has over the years build a deep understanding of the automotive industry due to its partnership with leading automobile manufacturers and original equipment manufacturers (OEMs) and their close involvement with them to develop effective solutions for the rapidly changing demands.

Manufactures today are working to come out with more fuel efficient vehicles, eco-friendly production and assembly methods. To achieve this, they are using lightweight materials that meet their need. Higher engine temperatures and pressures place extra demands on silencing, sealing and filtering components. Superior silencing materials are also required to enhance comfort in vehicle interiors. The range of custom made foams from Monarch helps fulfil these needs. Our product range for automotive and transportation includes:

Electric Vehicles

Electric vehicles are the future of transportation. The key challenges the manufacturer faces are; cost, range (weight is a critical factor), temperature issues, material quality in the vehicle.

Monarch is working with many different types of foam materials to counter the challenges and make the EV vehicle transportation safe. We are giving manufacturers products with excellent fire resistance properties. When combining this property with their insulative, lightweight and structural characteristics, our products provides a much safer building option to the automotive manufacturers.

We are offering critical material properties such as low thermal conductivity and low heat transfer. These features are being used to combat dangerous thermal runaway conditions. The low heat transfer and strength help contain temperature runaway while the low flame, smoke and toxicity (FST) properties reduce the risk of fire during catastrophic events. Our approach is to contain the fire before it spreads. Our solutions address the needs of:

DG Set

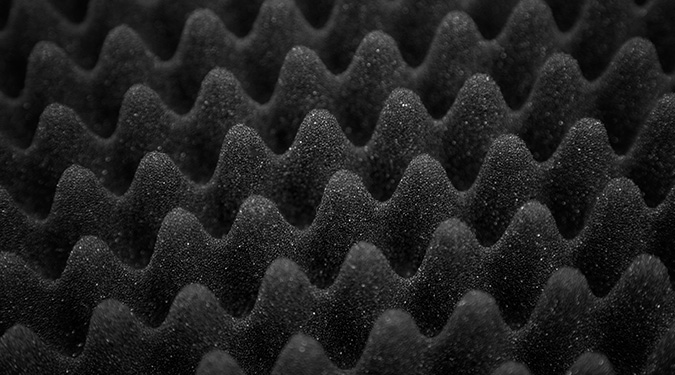

Monarch was a pioneer in working with a leading DG set company to replace rockwool with fire retardant Acoustic PU foam.

Healthcare

Monarch has also been a key supplier in this segment. Comfort, hygiene and cost-efficiency are key needs of healthcare sector. Foams find numerous medical applications:

PACKAGING

Based on the fragility and the toughness of the product

Different kinds of foams can be used for packaging. The fact that they are easy to

The Construction Industry

It is the biggest user of different kinds of foam. The industry uses both flexible and rigid foam for various applications.

Bedding And Furniture

This industry is the second largest consumer of foam material. Different kinds of foam based on the requirement, leisure, domestic, medical, special requirements are used.

Sports and leisure

Different types of foams are used here to suit the game and the sport requirement. They are used in a wide variety of applications due to their versatility, light weight, durability, ease of processing and cost efficiency. Products are made from them for sports like Cricket, Hockey, Football, Cycling, Yoga, Aerobics, Judo, Gymnastics, Kabbadi etc.

Refrigeration and Freezers

Foam has excellent heat insulation properties. They help improve energy efficiencies and reduce power loss. They also provide good anti-vibration properties.

Electrical and Electronics

Foams with anti-static properties are used to create trays, cushions and other packaging designs for sensitive electronic equipment. They are also used for packing protection for, other electronic equipment like,